The Essential Role of **Label Applicator Machines** in Modern Business

In today's fast-paced commercial environment, efficiency and accuracy are paramount. One critical component that ensures these aspects are met is the label applicator machine. This article delves into the functionality, benefits, and diverse applications of label applicator machines within businesses, particularly in sectors such as printing, electronics, and computers.

What is a Label Applicator Machine?

A label applicator machine is an automated device designed to apply labels to products, packaging, or other surfaces with high precision and speed. These machines come in various types and sizes, catering to different industry needs. From small-scale operations to large manufacturing plants, the versatility of label applicator machines makes them an invaluable asset.

The Mechanics of Label Applicator Machines

Understanding how a label applicator machine works can help businesses appreciate its value. Most models function by unwinding labels from a roll and applying them to a designated product or surface. Here’s a brief overview of how these machines operate:

- Label Dispensing: The machine pulls a label from its roll using a feed mechanism.

- Label Positioning: An alignment system ensures the label is correctly positioned for application.

- Adhesive Activation: Depending on the type of machine, the adhesive on the label is activated through pressure, heat, or moisture.

- Application: The label is then applied onto the surface with precision, ensuring proper adhesion.

Key Benefits of Using a Label Applicator Machine

Incorporating a label applicator machine into your business operations offers a myriad of advantages:

1. Increased Efficiency

Automating the labeling process significantly reduces the time and labor costs associated with manual labeling. With a label applicator machine, businesses can apply labels at remarkable speeds, enhancing overall productivity.

2. Improved Accuracy

Human error is inevitable, especially in manual processes. A label applicator machine ensures precise placement and consistent application of labels, reducing mistakes and ensuring compliance with regulations.

3. Enhanced Consistency

Consistency is crucial in branding. Automated label application guarantees that every product is labeled uniformly, reinforcing brand identity across all products.

4. Flexibility in Labeling

Many label applicator machines can handle various label sizes, shapes, and materials. This flexibility allows businesses to adapt to changes in product lines without the need for extensive modifications.

5. Reduction in Waste

With improved precision and automation, businesses can minimize label wastage, leading to cost savings and a more sustainable operation.

Applications of Label Applicator Machines Across Industries

The versatility of label applicator machines makes them suitable for a wide variety of industries:

Printing Services

In the printing sector, label applicator machines are instrumental in ensuring that printed materials are labeled effectively, whether for shipping, product identification, or branding purposes. They streamline production lines and improve delivery times.

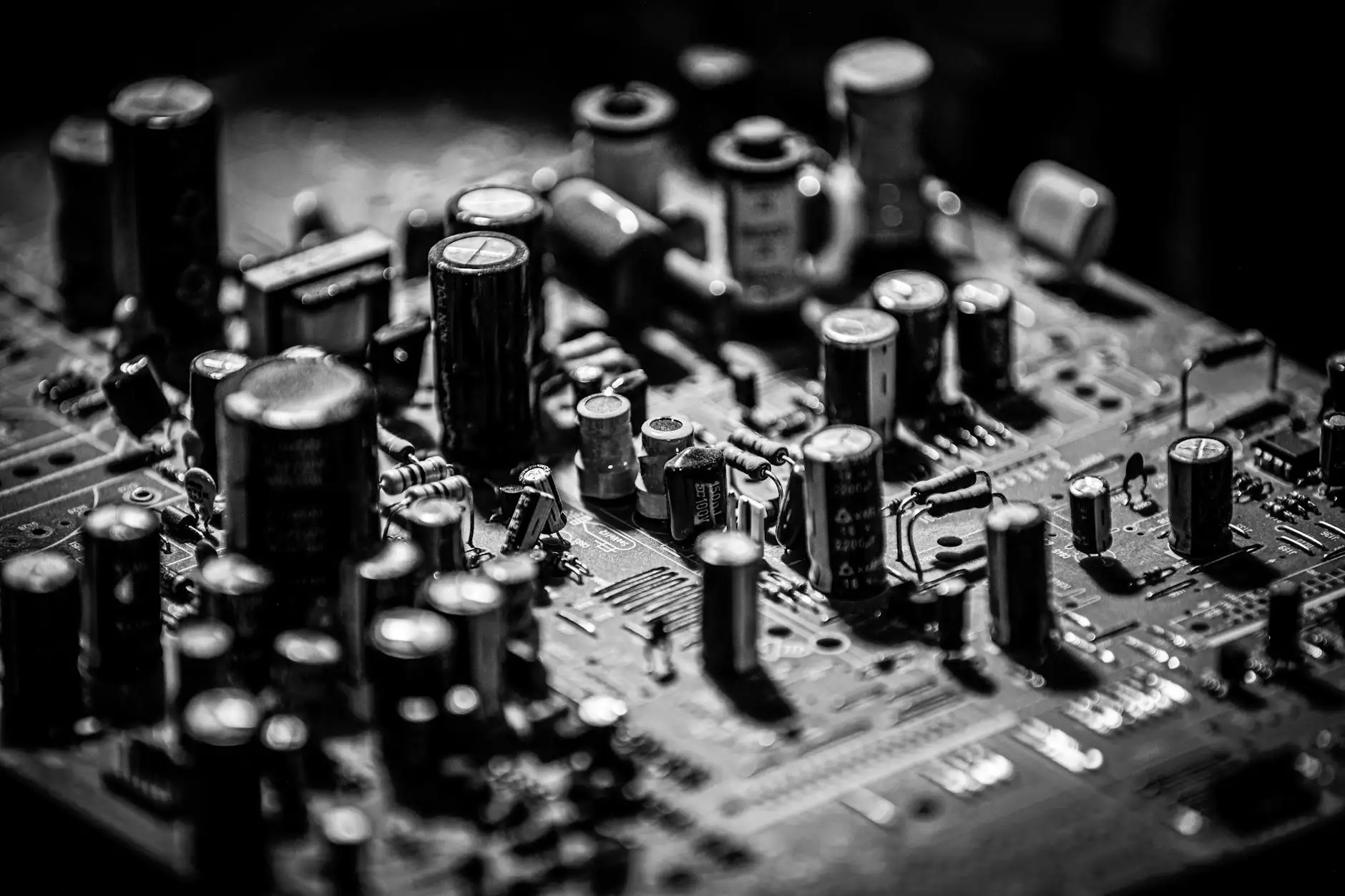

Electronics

For electronics manufacturers, precise labeling is essential for compliance and consumer information. Label applicator machines facilitate the accurate application of labels on small or intricate components, helping brands meet industry standards efficiently.

Computers and Technology

In the tech industry, products often have multiple labels, such as barcodes, serial numbers, and instructional information. A label applicator machine can apply various labels correctly, aiding in inventory management and product tracking.

Choosing the Right Label Applicator Machine for Your Business

When considering a label applicator machine, it's essential to evaluate your business's specific needs. Here are critical factors to consider:

- Speed: Assess the output requirements. Some machines offer much higher application speeds than others.

- Label Size and Material: Ensure the machine can handle the label dimensions and materials you intend to use.

- Integration: Choose a machine that can integrate easily with existing production lines for seamless operation.

- Ease of Use: Look for machines with user-friendly interfaces to reduce training time for operators.

- Maintenance and Support: Consider manufacturers that offer robust customer support and maintenance services to keep your operations running smoothly.

Cost Considerations for Label Applicator Machines

Investing in a label applicator machine is a significant decision for any business. While the initial cost can vary, it's crucial to consider long-term benefits, including labor savings, reduced errors, and increased production capacity. Businesses should perform a thorough cost-benefit analysis to ensure that they choose the right machine that fits both their budget and operational needs.

Future Trends in Label Applicator Technology

As industries continue to evolve, so too does the technology behind label applicator machines. Here are some trends to watch:

- Smart Technology: Advances in IoT will allow for smarter machines that can collect data, track performance, and predict maintenance needs.

- Eco-Friendly Materials: The push for sustainability is influencing the development of machines that can handle biodegradable or recycled label materials.

- Customization: Customization capabilities will increase, allowing businesses to create labels on-the-fly, adapting to market trends faster.

Investing in a Label Applicator Machine: Is It Right for You?

For businesses looking to enhance their efficiency, accuracy, and overall productivity, investing in a label applicator machine may be one of the best decisions they can make. By understanding the capabilities, benefits, and applications of these machines, companies can streamline their processes and solidify their position in an increasingly competitive market.

Conclusion

In conclusion, the role of a label applicator machine in modern business is paramount. By automating the labeling process, businesses can achieve higher efficiency, consistent quality, and a clear competitive edge in their respective markets. As technological advancements continue to shape the industry, companies that adopt these machines will be better prepared to meet the challenges and demands of the future.

For more information on selecting the right label applicator machine and to discover other printing solutions, visit omegabrand.com.